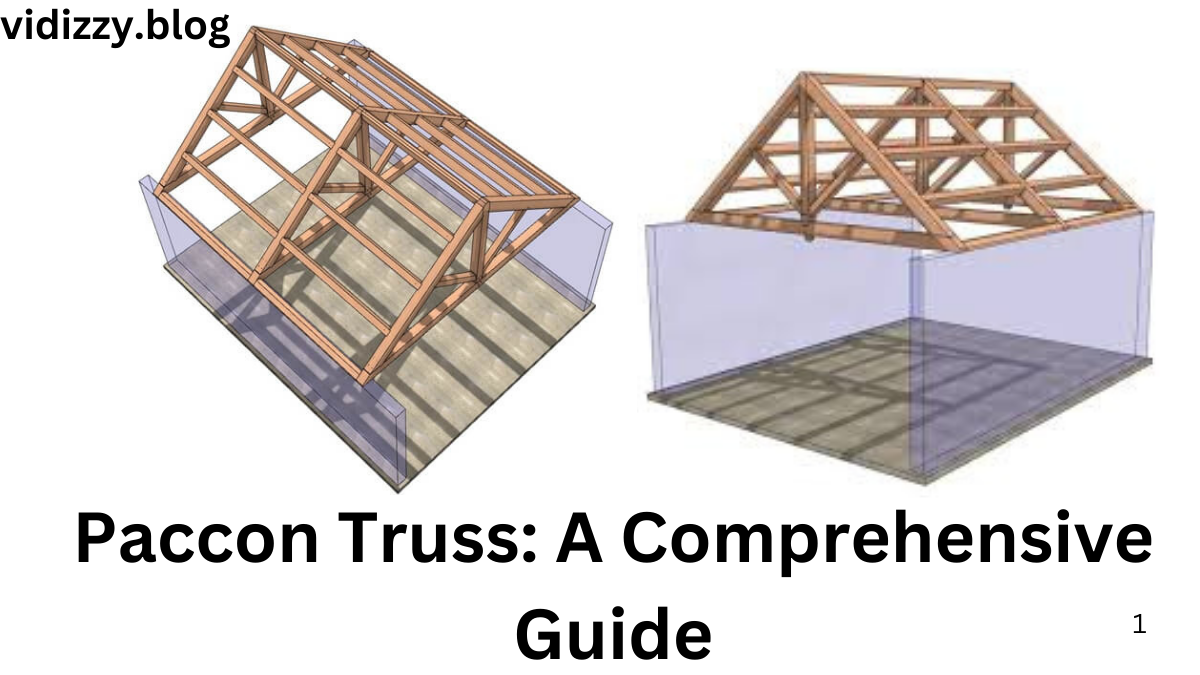

Paccon Truss: A Comprehensive Guide

In the world of construction and architecture, trusses play a vital role in providing structural integrity to buildings, bridges, and roofs. Among the many innovative truss systems available, Paccon Truss has become a standout choice for engineers and architects due to its unique design, durability, and efficiency. This article explores Paccon Truss in detail, covering its design principles, applications, advantages, and the latest trends in truss technology.

What is Paccon Truss?

Paccon Truss is an advanced truss system known for its superior design and engineering. It is widely used in the construction industry for various applications, including commercial buildings, residential projects, bridges, and roofing systems. Paccon it stands out for its ability to provide strength and stability while minimizing material costs, making it an ideal choice for large-scale construction projects.

Understanding Trusses and Their Importance in Construction

What is a Truss?

A truss is a framework of beams or bars that are arranged in a triangular shape to provide support and distribute loads across a structure. Trusses are often used in construction for roofs, bridges, and other supporting frameworks. The purpose of a truss is to reduce material waste while maintaining the required structural integrity.

Why Are Trusses Important?

- Efficiency: Trusses help in distributing weight evenly across a structure, reducing the amount of material needed for construction.

- Strength: A well-designed truss provides strength without the need for large, bulky materials.

- Versatility: Trusses are flexible and can be used in various construction types, from residential to industrial projects.

Overview of Paccon Truss Design and Features

Key Features of Paccon Truss

- Lightweight Construction: Paccon it systems are engineered to be lightweight while maintaining high strength. This reduces the load on supporting structures.

- Modular Design: The modular nature of Paccon it allows for easy customization, whether you’re designing for a residential home or a large commercial structure.

- Durability: Paccon it systems are designed to withstand harsh environmental conditions, making them suitable for both indoor and outdoor applications.

- Ease of Installation: Paccon it systems are designed for ease of assembly, reducing labor costs and construction time.

Types of Paccon Trusses

- Roof Trusses: Primarily used in roofing, these trusses offer support and stability for various roofing materials.

- Bridge Trusses: Used in bridge construction, providing support for roadways or railways while maintaining load distribution.

- Floor Trusses: Utilized in floor construction to support heavy loads, especially in multi-story buildings.

Applications of Paccon Truss

Residential Construction

Paccon Truss is commonly used in residential buildings, where it supports the roof and floor structures. The trusses are pre-fabricated, making them easier to transport and install.

Commercial and Industrial Buildings

In commercial and industrial settings, Paccon it are often used to support larger, more complex roofing and flooring systems. They offer stability while minimizing the amount of raw material needed for construction.

Bridges and Infrastructure

Paccon Trusses are also extensively used in the construction of bridges, where their ability to bear significant loads without requiring a large amount of material makes them an ideal choice.

Agricultural and Warehouse Structures

Paccon it are used in agricultural buildings and warehouses to create large open spaces without the need for supporting columns, providing efficient storage solutions.

Advantages of Using Paccon Truss Systems

Cost-Effectiveness

Paccon it reduce the overall construction costs by using less material compared to traditional support structures, and the modular design reduces labor costs. Their lightweight nature makes shipping and handling easier, further saving money.

Enhanced Structural Integrity

Due to their precise engineering, Paccon Trusses can carry heavy loads without compromising stability. This makes them ideal for large-scale projects that require both strength and efficiency.

Faster Construction Time

Since Paccon it are prefabricated in a factory and then assembled on-site, the construction process is significantly faster compared to building custom frames or supports.

Environmental Benefits

The materials used in Paccon Trusses are carefully selected to reduce waste. Their efficiency in using fewer resources makes them a more sustainable option for construction.

Versatility

Paccon Trusses are suitable for a wide range of applications, from residential homes to bridges and industrial facilities. This versatility makes them a go-to solution for engineers across various sectors.

Paccon Truss Materials and Manufacturing Process

Materials Used in Paccon Trusses

Paccon Trusses are typically made from materials like steel, wood, or aluminum, depending on the application and load requirements.

- Steel: For heavy-duty applications like bridges and industrial buildings.

- Wood: Common in residential and low-load-bearing structures.

- Aluminum: Often used in lightweight or corrosion-resistant applications.

The Manufacturing Process

The process of creating Paccon Trusses involves several steps:

- Design Phase: Engineers design the trusses using specialized software to ensure they meet the load requirements and project specifications.

- Material Selection: Based on the intended use, the appropriate materials are chosen.

- Fabrication: The components are fabricated in a controlled environment to ensure high precision.

- Assembly and Testing: The trusses are assembled and undergo rigorous testing for strength, durability, and safety.

- Delivery and Installation: The pre-assembled trusses are delivered to the construction site for quick installation.

Case Studies: Successful Applications of Paccon Truss Systems

Residential Project

A recent residential project used Paccon Trusses for roofing in a large suburban development. The ease of installation and strength of the trusses reduced the construction timeline by 20%, allowing the builders to complete the project ahead of schedule.

Commercial Warehouse

A commercial warehouse in a coastal area required a truss system that could handle heavy snow loads and high winds. Paccon it were selected for their durability, and the project was completed on budget and within the required safety specifications.

Bridge Construction

Paccon it were used in a bridge project connecting two rural areas. The pre-engineered trusses provided significant cost savings and allowed for faster completion compared to traditional bridge construction methods.

Future Trends in Truss Technology

Smart Trusses and IoT Integration

The future of truss systems, including Paccon it, lies in smart technologies. Incorporating sensors and Internet of Things (IoT) devices into trusses can help monitor structural health and detect issues like stress and corrosion in real-time.

Sustainable and Eco-Friendly Materials

As sustainability becomes a key focus in construction, the development of eco-friendly truss materials will continue to evolve. Research into biodegradable or recyclable materials could play a pivotal role in the future of Paccon Trusses.

3D Printing and Truss Manufacturing

3D printing technology may revolutionize the way trusses are manufactured in the future. This technology could enable more complex designs, faster production times, and even more sustainable materials.

Conclusion

Paccon Truss systems have proven to be an innovative and reliable solution in modern construction. Offering benefits such as cost-effectiveness, strength, versatility, and speed, these trusses are ideal for a wide range of applications—from residential homes to large industrial projects. As construction technology continues to evolve, Paccon it remain at the forefront of innovation, paving the way for more efficient, sustainable, and reliable building practices.